DESTINATION: ITALY

INDUSTRY: FOOD/DRY VEGETABLES

REQUIREMENT:

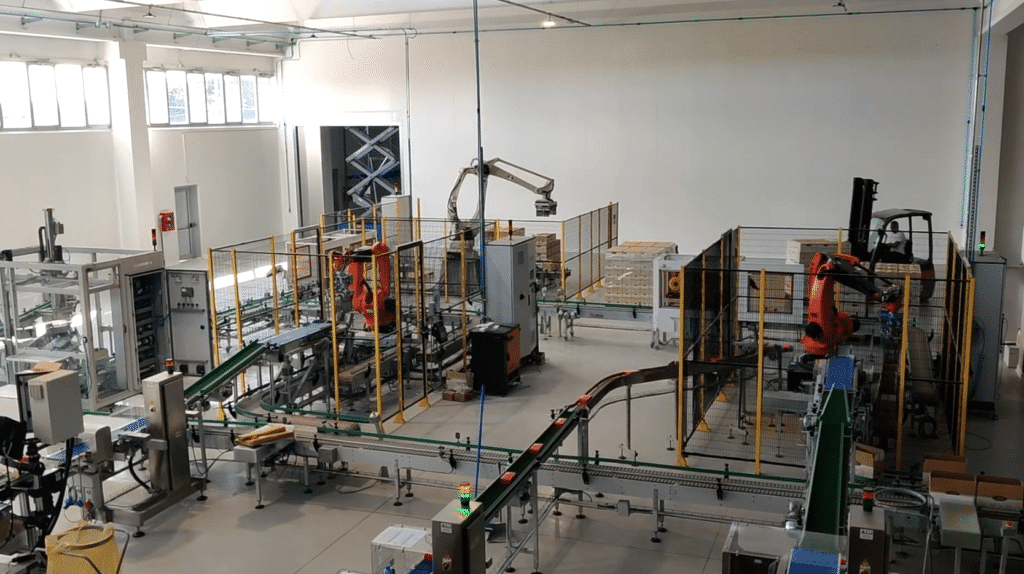

Multi purpose robotic solution for case packing and palletising to handle cartons and bags of dry vegetables in different formats, from 300gr to 5kg. Main purposes are reduction of manpower, improvement of ergonomics, increase production efficiency of the line and of the quality of the finished product on the shelves

DESCRIPTION OF THE SCOPE OF SUPPLY:

The end of line, entirely designed and manufactured by Comega, collects the products from the existing primary packaging machinery.

1 cartoner and 3 bagging machines and convey to the different case packing lines as follows:

- an anthropomorpf robot case packing line to handle both bags and cartons, with independent pattern preparation and picking stations. The line can handle a wide range of formats, from 300gr to 5kg

- an anthropomorpf robot case packing line to handle both bags, with independent pattern preparation and picking stations depending of bags formats

- a 2 axis case packer to handle bags from 300gr to 500gr through pattern preparation station and pick&place arm

- an anthropomorpf robot palletizer with 2 pallets stations to cover the whole production

The whole line is managed through a Main controller whose software has been developed 100% by Comega for the supervision of the entire line and capable to optimize product flows, ensure maximum productivity and efficiency, provide statistical data.

An operator recognition system via RFID technology allows dedicated access in total safety.